73

73

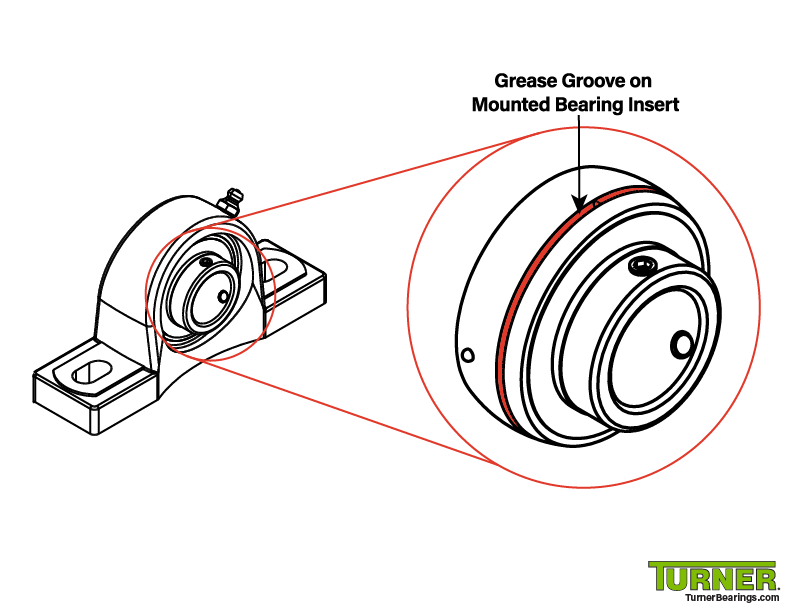

A Lubrication groove - or grease groove - is a groove in metallic bearings that distributes lubricants, oils, and grease.

Lubrication grooves are typically found on the top or outside of the outer race. In some designs, they can also be found inside the housing or on the inside of the inner ring.

Lubrication grooves are essential for distributing lubrication to components that require grease.

Grease is difficult to distribute evenly, making a lubrication groove beneficial. The grease groove allows the grease to be distributed to typically three evenly spaced holes. Most commonly, grease is injected through a grease port or a zerk on the housing.

Proper lubrication preserves bearing lifespan and prevents friction which can cause rapid wear and tear. Without proper lubrication, bearings can fail.

Lubrication grooves allow for better efficiency.

Not all applications have easy-to-reach parts. Lubrication grooves allow the application of lubricant to hard-to-reach areas. When equipment is properly lubricated, it minimizes unforeseen downtime and maximizes production.