82

82

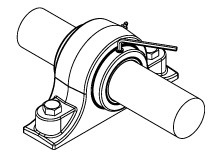

INSTALLATION INSTRUCTIONS

STEP 1 – SHAFT PREPARATION

Wipe the shaft clean and remove any burrs that could cause the bearing race to deform when the setscrews are tightened down. Proper shaft diameter is CRITICAL. Check the shaft diameter against the specifications shown in Table 2. Undersized shafting is one of the leading causes of bearing failure. If the shaft is not within the tolerance shown in Table 2, its use may lead to premature bearing failure.

STEP 2 – BASE PREPARATION

Make sure that the base of the mounted bearing and support surface are clean and flat. Any unevenness in the surface can interfere with proper bearing alignment and lead to premature failure.

STEP 3 – MOUNTING OF HOUSING

Slide the bearing on the shaft to the desired position. DO NOT use anti-seize style lubricant on the shaft or bearing. Leave the setscrews loose. Use shims where necessary to properly align the bearings.

STEP 4 - SECURE THE BEARING

Securely fasten the mounted bearing to the support surface using the machinery manufacturer’s recommendations. Alternately tighten both setscrews until both setscrews are locked to the shaft at the proper torque shown in Table 1.

STEP 5 - CHECK ALIGNMENT

Turn bearings by hand. The effort required to turn the bearing should be the same before and after tightening to the housing support.

Table 1-Set Screw Torque Table

| Shaft Size (inches) | Set Screw Size | Tightening Torque |

|---|---|---|

| 1-3/16—1-11/16 | 5/16—18 | 165 in-lbs |

| 1-3/4—2-1/2 | 3/8—16 | 290 in-lbs |

| 2-11/16—3-1/2 | 1/2—13 | 620 in-lbs |

| 3-15/16—5 | 5/8—11 | 1325 in-lbs |

Table 2

| Shaft Diameter | Shaft Tolerance |

|---|---|

| up to 1 1/2” | +0.000” -0.0005” |

| 1 5/8” - 4” | +0.000” -0.0010” |

| 7/16” - 5” | +0.000” -0.0015” |

If all the steps above have been followed, the bearing mounting is complete.

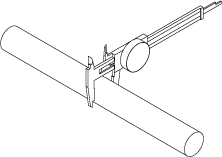

REMOVAL INSTRUCTIONS

Loosen the setscrews from the shaft. Then unbolt the housing from the support surface. Often, the bearing will adhere to the shaft. In this situation, use a bearing puller or hammer and drift to remove the bearing. Check for proper shaft fits, shown in Table 2, prior to the next installation.

RELUBRICATION INSTRUCTIONS

Turner Mounted Tapered Roller Bearings will come from the factory with pre-installed Shell Gadus S2 V220 at 1/3 fill. For relubrication intervals, follow the guidelines below.

- Determine the maximum allowable RPMs of your bearing in the MAX RPMs chart below.

- Determine the percentage of maximum RPMs at which your bearing will operate.

- Use the Lubrication Interval Chart to determine your relubrication intervals in weeks.

Max RPMs (Per shaft dia.)

| Shaft Dia. | Max RPMs |

|---|---|

| 1-1/4 | 4,490 |

| 1-3/8 - 1 7/16 | 3,820 |

| 1-1/2 - 1-11/16 | 3,320 |

| 1-3/4 - 2 | 3,050 |

| 2-3/16 | 2,730 |

| 2-1/4 - 2-1/2 | 2,420 |

| 2-11/16 - 3 | 2,060 |

| 3-3/16 - 3-1/2 | 1,640 |

| 3-15/16 | 1,530 |

Lubrication Intervals Chart (in weeks)1

| Speed (RPMs) | |||

|---|---|---|---|

| Environment | <25% of Max | 25%-75% of Max | >75% of Max |

| Clean (ideal) |

52 | 8 | 2 |

| Moderate Exposure |

4 | 3 | Monitor2 |

| Extreme Exposure |

1 | 1 | Monitor2 |

1Based on 8 hrs. per day operation

2Monitor bearing for signs of overheating

Examples:

- A 1 15/16” sized bearing running at 1750 RPMs is running at 57% of max RPM. (1750/3050 = .573; or 57%)

- A 3” sized bearing running at 1750 RPMs is running at 85% of max RPM. (1750/2060 = .849; or 85%)

Associated Part Numbers

- TRN EPB2 Type-E Pillow Blocks

- TRN EPB4 Type-E Pillow Blocks

- TRN EFB4 Type-E Flange Blocks